Can McLaren wheel withstand DD2?

Hi,

I have DD2 and Formula v2 wheel, but I don't like this wheel a lot and want to buy MaLaren wheel. It much more comfortable.

But many people says, what it can't withstand power of DD2.

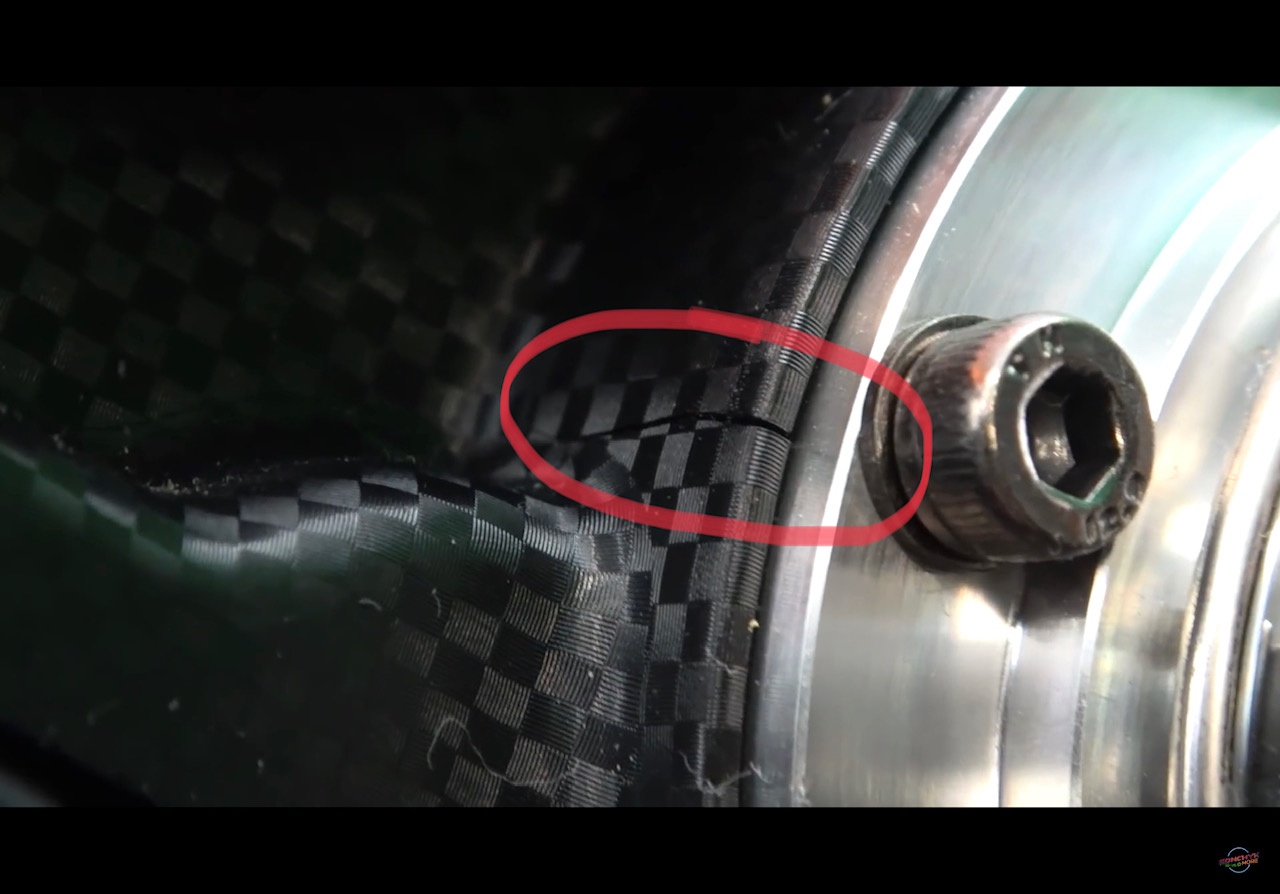

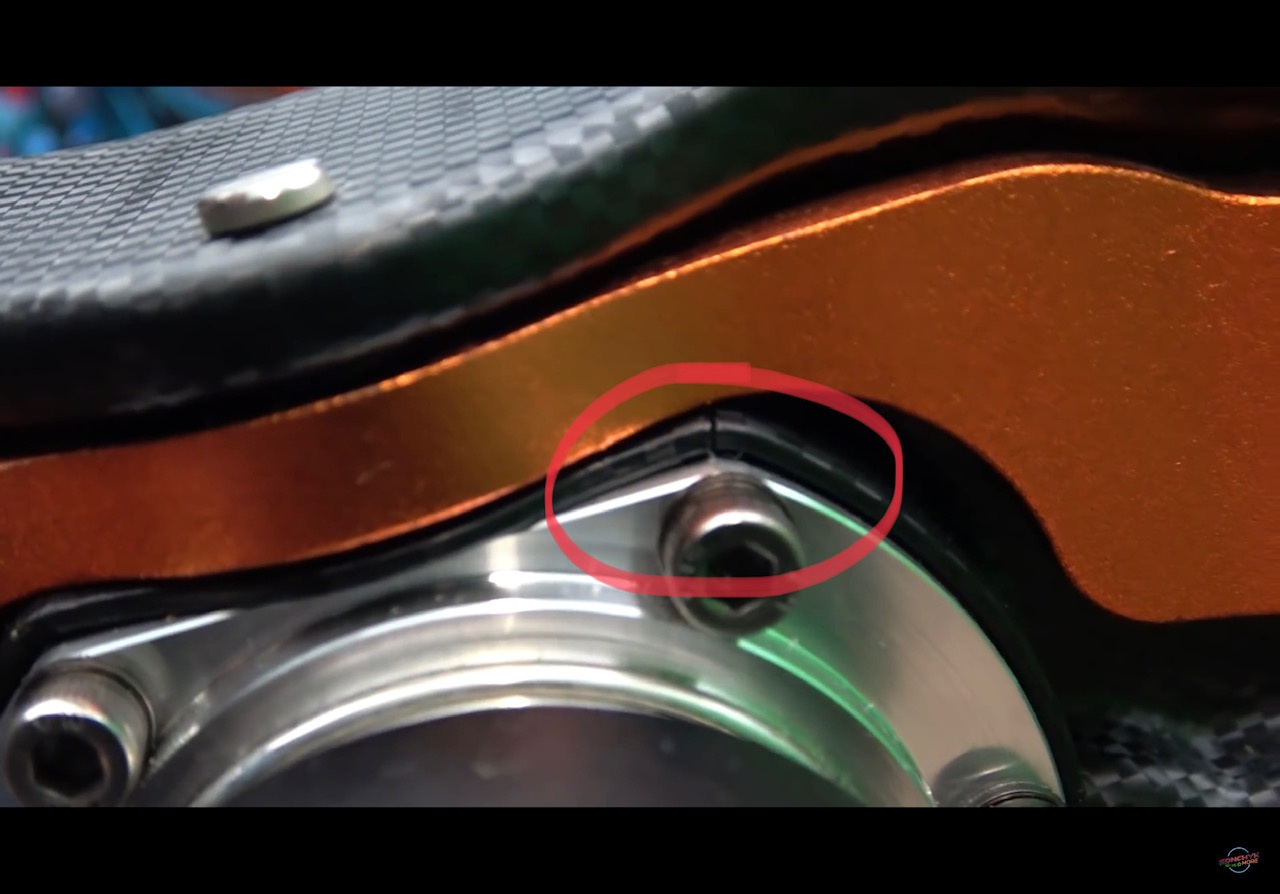

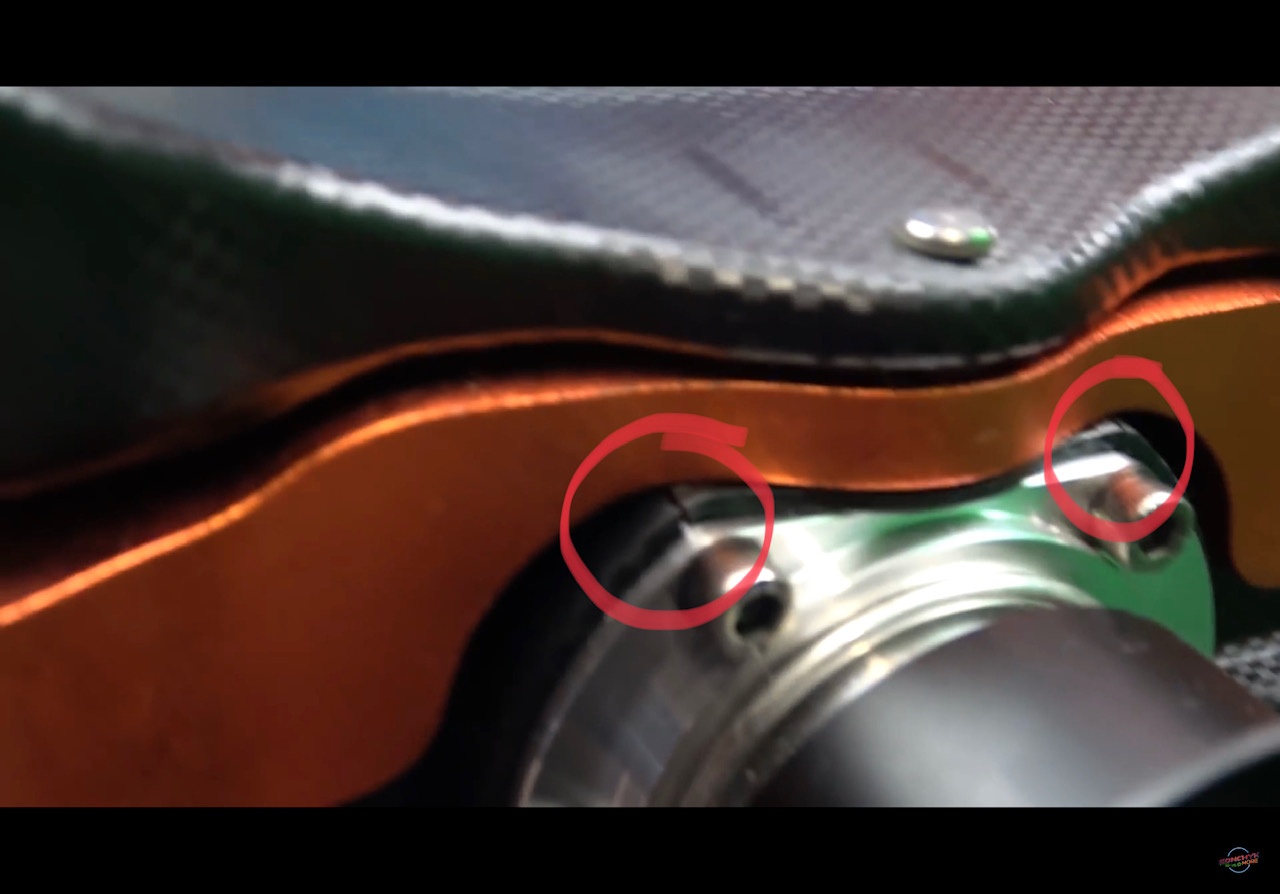

I saw 3(!) McLaren wheels with such issue after a few days using on DD1 oк DD2:

So guys, what do you think, is it typical problem or something unusual?

P.S. I bought new Porsche wheel too, but it's very heavy and for cars like Formula Renault 3.5 in iRacing ect I would like to have light "formula" wheel.

Comments

I'm not clear what you're asking. You seem to have answered your own question with the pictures that you attached to your post and you even clarified that this has been seen more than once online.

Are you asking to seek confirmation bias?

Are you asking Fanatec to re-design the McLaren wheel for the DD wheel bases?

Are you asking whether you can get a warranty replacement when your wheel breaks under suspected high torque?

Are you asking whether you should attempt a home repair yourself?

Are you pointing this out to poke fun at the Made in China quality? or the Designed in Germany quality?

Dimitry

I have been using dd2 with Mclaren since the first batch April I think with no issues

I think he is asking in order to establish if the 3 damaged examples are outliers or if this damage is routine. Seems clear to me and a sensible thing to do, we know that it can be difficult to determine proportionality from internet reports; people with problems post, people without problems do not post - they race. :-)

So in response to the OP, I use my McLaren wheel on my DD2, I have not used it for long, only had the DD2 less than a month but I don't sense any issues with the McLaren wheel. I have my wheel set up so max force on the most extreme downforce cars is around 14 N m and it handles that force with no flex or creaking.

I have used the MCL with QR and no issues. These photos seems like the screws were over torqued from where the fracture is located. Also I would suggest adjusting your ffb to accommodate each wheel, running higher NM with Podium or Clubsport Wheels and slightly lower with CSL series.

r/whoosh ;)

Ah! Your post was a joke! And there was me thinking your response was simply condescending. Thanks for clearing up my error. 😘

There is only one sentence with sign "?" at the end.

I think you are right indeed. over torque

I don't have any CSL wheels but what you suggest is that the hub is supported by the plastic and the plastic is not just a shroud. Also you suggest that the failure mechanism is not from the base, but in fact from installation error.

If the wheel broke from installation error, people would not suggest that the torque of the DD base is greater the material yield strength. If this was an issue of over torque, then Fanatec should provide torque specs. Since no torque specs are given, this conclusion cannot be supported otherwise Fanatec is just negligent in providing torque specs.

Well, I just agreed with Joseph and judged from the pictures of cracks. fanatec provides the torque spec as "don't use the long arm of the allen key".

But exactly this wheel (on photo) worked a year with ClubSport 2.5, and cracks appeared after a few days using with DD2...

Wait, so you have a formula wheel that you don't like......but you want to buy another formula wheel? Your post is confusing. As for the McLaren, I've been using one with the DD1 for months and never had a single issue. I don't race at 100% force feedback because that would be absurd so I can't speak to that scenario. The wheel pictured was likely broken because they overtightened the bolts. But if you use a McLaren rim with the new QR in normal use case scenarios then it should work fine.

Wait, so you have a formula wheel that you don't like......but you want to buy another formula wheel?

It's a very different wheels with different size. McLaren is very comfortable by opinion of many people. F v2 not comfortable by my opinion (and many people too).

The McLaren is not a formula rim; it's a GT rim. Your post is confusing! ;-)

Lost in translation ^_^

I have the same if not worse issue using the 8nm CSL DD at 75%

And I used a torque wrench set at 3nm